Description

In this project we give a special idea of industrial automation, and fault monitoring. Induction motors are the nerves of many industries. Hence industrial automation is required for precise and accurate operation. The project Arduino-based parameter monitoring system for induction motor proposes a control and monitoring system for induction motor based on Arduino communication protocol for safe and economic data communication in industrial fields. The current, voltage, and temperature of the induction motors are very important parameters for its control system. The performance of an induction motor is directly affected by these fundamental quantities. However, during continuous operation, it is difficult to control the machines. Arduino system is used for collecting and storing data and generate control signals to start or stop the induction machine. We measure the different types of fault such as Over Voltage, Over Current, and Over Temperature.

Nowadays, the induction motor has remained the most popular type of motor for industrial applications. Monitoring and controlling of induction motor parameters are very essential in many applications and also for reliable operation there are several techniques available for the same. This paper deals with the monitoring of various parameters & control of three-phase induction motor remotely based on the Internet Of Things [IOT]. A module of sensor and transducers monitors the parameters like temperature, current, and voltage of induction motor and send to the processing unit which will display parameter on the server. The system also presents the automatic and manual control methods to stop or start the induction motor to avoid any system failures through the server gateway. The Implementation of this scheme will increase the working efficiency of machines by continuously monitor to avoid breakdowns and also to determine the preventive maintenance.

Note

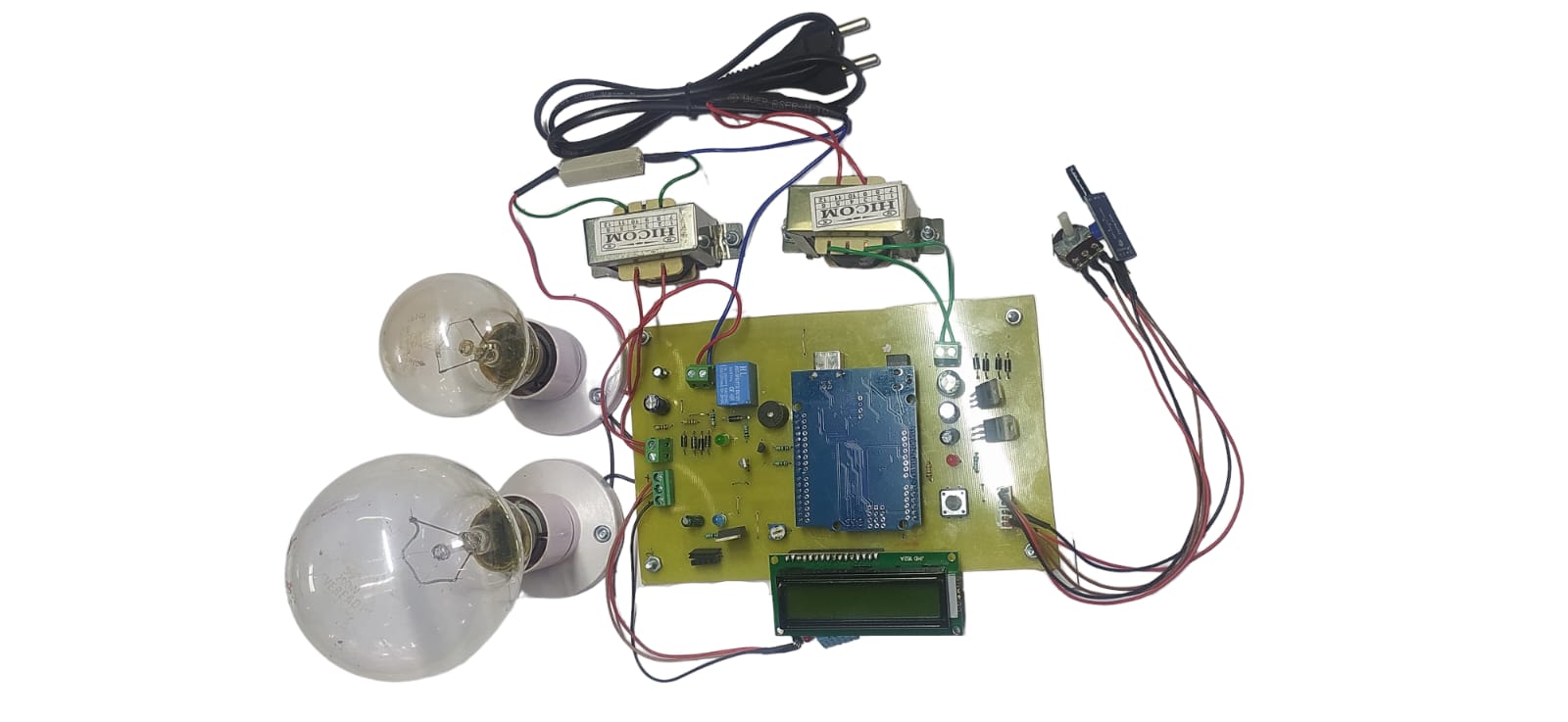

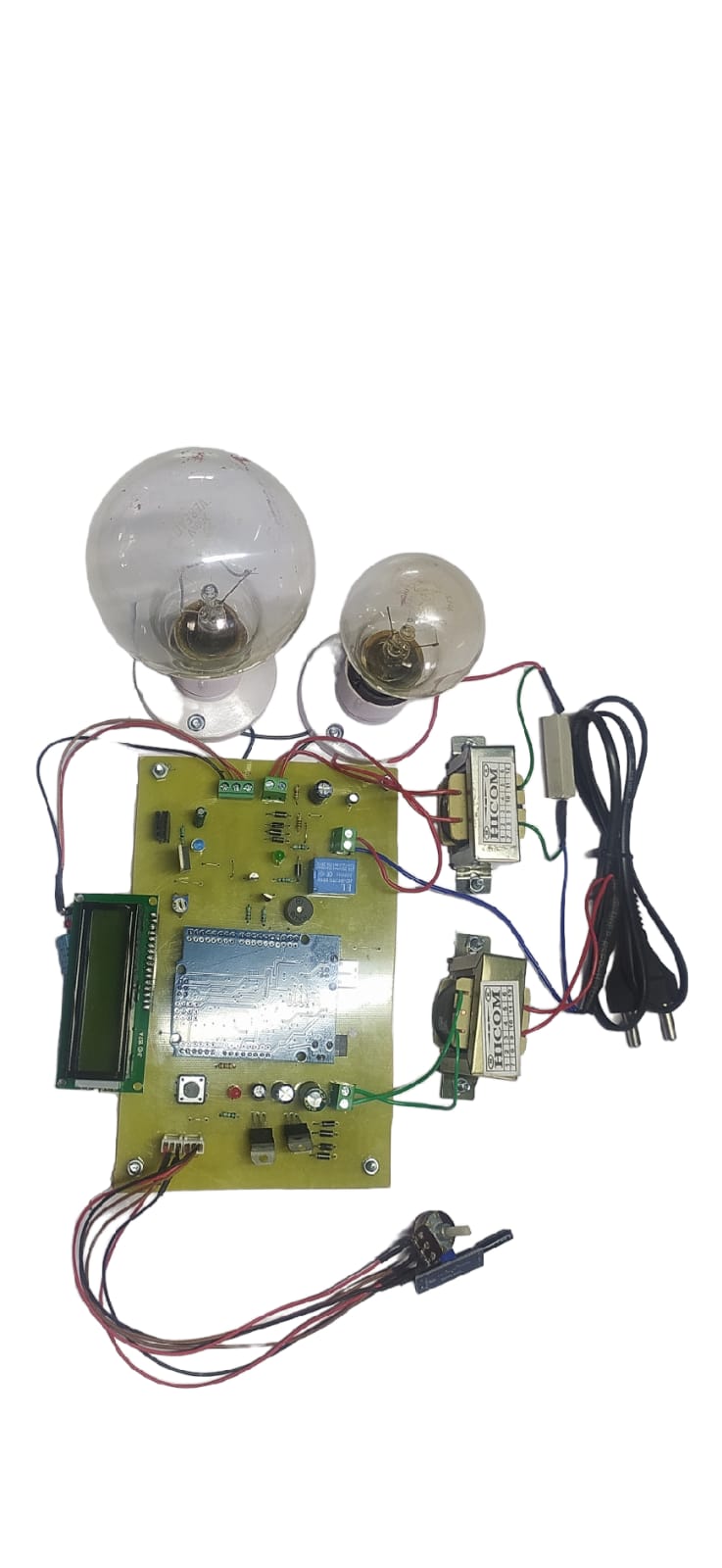

Induction motor protection system and data monitoring over iot blink app is the project of last year’s engineering project, BE final year engineering project. This project is used for BE last year electrical, electronics, core electrical department students is used. This project is core electronics based project. This project is use for the electrical students. This projects is iot based projects

Induction motor protection system and data monitoring over iot blink app.it is a very comparative engineering project and electrical project electronics project. It is a very good BE core electrical final year and diploma final year core electrinics based project.it is project for arduino based project idea for the electrical projects is a iot blink app based project.

The engineering projects give in the ELECTROSAL HI- TECH PVT.LTD. The best place for the degree and diploma final year engineering projects as well as for electrical students ‘electronics student final year for the golden opportunity.

Induction motor protection system and data monitoring over iot blink app is an easy project and idea for the electrical degree and diploma and electronics base students & 100% output is done.

HIGHLIGHTS

- In this project the concept of the Internet of Things

for monitoring motor system parameters remotely. - The project uses the Blynk platform

- Early detection of motor failure.

- The system has the specific advantage of less

maintenance.

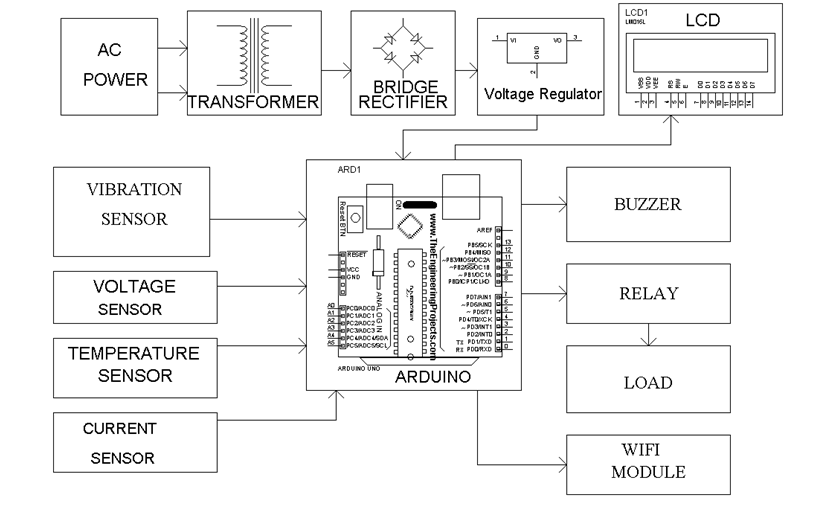

BLOCK DIAGRAM

HARDWARE REQUIREMENTS

- Arduino UNO

- Relay

- Buzzer

- ESP 8266 Wi-Fi Module

- Potentiometer

- Vibration Sensor

- DHT 11 Temperature Sensor

- Transformer

- Bridge rectifier

- Regulator

- LCD display

SOFTWARE REQUIREMENTS

- Arduino IDE

- Proteus

- Eagle

Suryakant –

I ordered this project on website of electrosal. I got this project only in two days and in good condition. Electrosal team given me a good support. Thank you Electrosal.

VICTOR KIPROTICH –

I ordered this project on website of electrosaL

electrosal –

Thank you Electrosal hi tech. They helped me a lot in my project work.once again thank you Electrosal team

Prajkata Shirgave –

Project got in time. Good service after delivery by video call. They giving one year warranty with peace to peace replacement. I really like service of ELECTROSAL. Thanks team and specially thanks Tulasidas sir who supported me lot in my project ” Automatic Power factor Correction