Showing 33–48 of 175 results

-

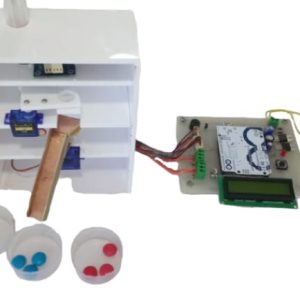

Autonomous Fire Fighting Robot Using Arduino

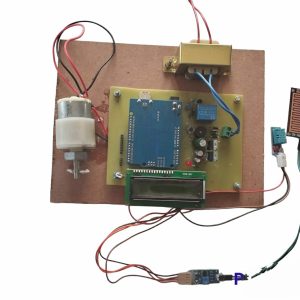

$186.31$168.28A fire outbreak is a hazardous activity that leads to numerous consequences. Detecting a fire at an early stage and extinguishing it can aid in the prevention of various accidents. Till now we rely on human resources. This often leads to risking the life of that person. Therefore, fire security becomes an important aspect to save human lives. In this, a fire extinguishing robot has been proposed and designed which detects the fire location and extinguishes the fire by using sprinklers on triggering the pump. This robot uses flame sensors for accurate fire detection. This proposed model of Fire Extinguishing Robot using Arduino is used to detect the presence of fire and extinguish it automatically without any human interference. It contains gear motors and motor drivers to control the movement of the robot when it detects any presence of fire and will automatically start the water pump to extinguish that fire breakout. This model robot has a water ejector which is capable of ejecting water at the fire breakout place. The water ejector pipe can be moved in the required direction using a servo motor. The whole operation is controlled by an Arduino UNO.

Fire-fighting is an important but dangerous occupation. A firefighter must be able to reach the situation quickly and safely extinguish the fire, preventing further damage and reducing fatalities. Technology has come to rescue this issue, fire-fighters and machines are now having more efficient and effective methods of fire fighting. This gives you the design idea of a fire-fighting robot using autonomous operation. The robotic vehicle is loaded with a fire extinguisher and a water pump which is controlled over the solenoid valve to throw water. An Arduino UNO is used for the desired operation. A water tank and fire extinguisher set up along with a water pump are mounted on the robot body and its operation is carried out from the output through the appropriate signal from the sensor. The whole operation is controlled by an Arduino UNO.

-

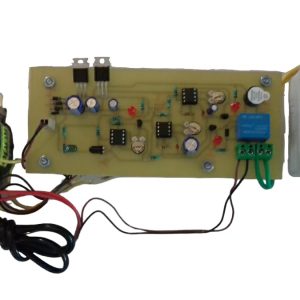

BLDC MOTOR SPEED CONTROL WITH RPM COUNT

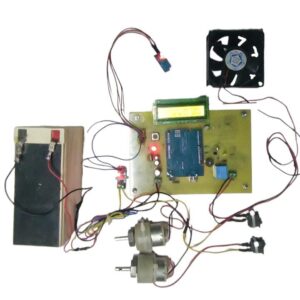

$103.37$91.35In this Project, the objective is to cont control of the machineries which involving this motor can be done accurately, thus making the industrial automation production rate increased.

In the prevailing case Brushless Direct Current motor are extensively used in some of the industries because of its low cost, noise less operation, high speed torque characteristics, Speed controlling is very essential.

-

Chemical Mixture Using Arduino

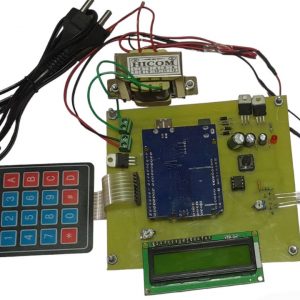

$204.34$192.32The main aim of the project is to process the real time acquisition under arduino for large scale remote industrial environment.

In large industrial establishments many processes go on, therefore it is essential to monitor all the processes and control the factors affecting them. Adapting a technology like Arduino (Arduino controller) one can achieve the above mentioned objective effectively

-

COLOUR BASED SORTING SYSTEM

$120.20$100.97For sorting object in industry optical sorting is very much convenient. Colour and size are the most important features for accurate classification and sorting of product which can be done by using some optical sensors. The colour sorting machine is mainly a device that can sense the different colour of the object and assert them into their respective location.

-

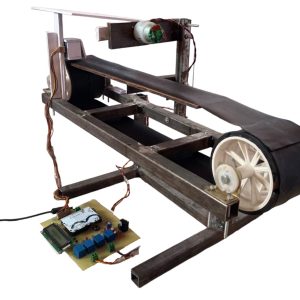

Colour Based Sorting System Using Conveyer Belt

$195.93$168.28Sorting of products is a very difficult industrial process. Continuous manual sorting creates consistency issues. a working prototype designed for automatic sorting of objects based on the color. TCS230 sensor was used to detect the color of the product and the Arduino microcontroller was used to control the overall process. The identification of the color is based on the frequency analysis of the output of TCS230 sensor. conveyor belts were used, each controlled by separate DC motors. The belt is for placing the product to be analyzed by the color sensor, belt is for moving the container, having separated the all colours in the convey belt in order to separate the products. The experimental results promise that the prototype will fulfill the needs for higher production and precise quality in the field of automation.

-

Dc Motor Rotation In The Clock Wise And Anti Clock Wise Direction Using Rf Remote

$40.87$28.85DC Motors are commonly used in electronics and electrical projects. It may be a line-following robot, a remote-controlled car, electronic shutters and doors, digital locks, drones, and choppers, etc; the DC motors are used in a variety of applications. This project is a simple demonstration of remote controlling a DC motor by switching it on or off and changing the direction of its rotation clockwise or anticlockwise

-

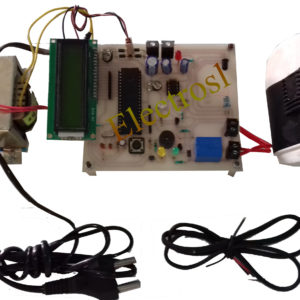

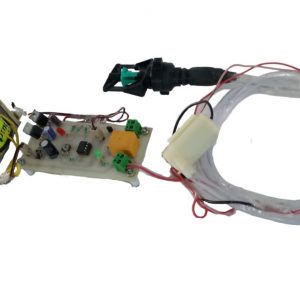

DETECTION OF FIRE AND ITS EXTINGUISHER

$34.86$22.24In this proposed system, the fire is detected using comparator IC. Here we are using comparator IC which is the main part of this project, fire sensor (thermistor) for the detection of fire, AC water pump will ON the foggier, foggier spray and power supply circuitry.

-

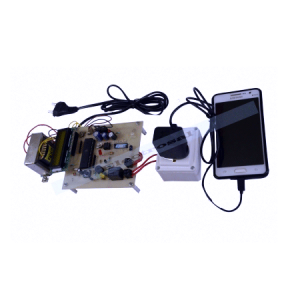

Diesal Generator Body Leakage Current Measurment And Auto Switching Based On Leakage Current

$114.19$100.97The emergency diesel generators in a nuclear power plant have an important safety function-supplying emergency electrical power to maintain cooling and other vital functions. The research reviewed in this article addresses the safety implications of aging of these emergency diesel generators and the influence of aging on their reliability. Historical operational information was assembled on component and system failures and their causes. One significant research result is that the fast-starting and fast-loading test procedure mandated by Regulatory Guide 1.108 and the standard Technical Specifications has contributed to wear and degradation. Other equally important aging and degradation factors for the diesel generators are identified and reviewed. A new approach developed represents a more balanced aging management program that includes (1) slow-start testing during which operating parameters are monitored.

(2) Analysis of data trends,

(3) Training.

(4) Maintenance.

This approach should improve safety by identifying aging degradation that leads to fitture diesel generator failures. Timely maintenance could then prev*ent actualJafiures.