Description

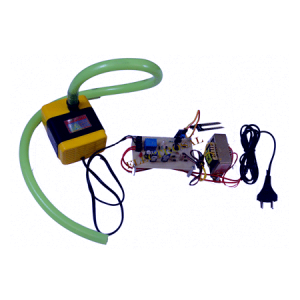

The main objective of this project is to develop a industrial automation system conveyer belt with water filling controlled by microcontroller. As technology is advancing so industries are also getting smarter. Modern industries are gradually shifting from conventional man power to centralized control system, involving controlled system. Presently, conventional water filling located in different parts of the industries makes it difficult for the user to go near to operate.

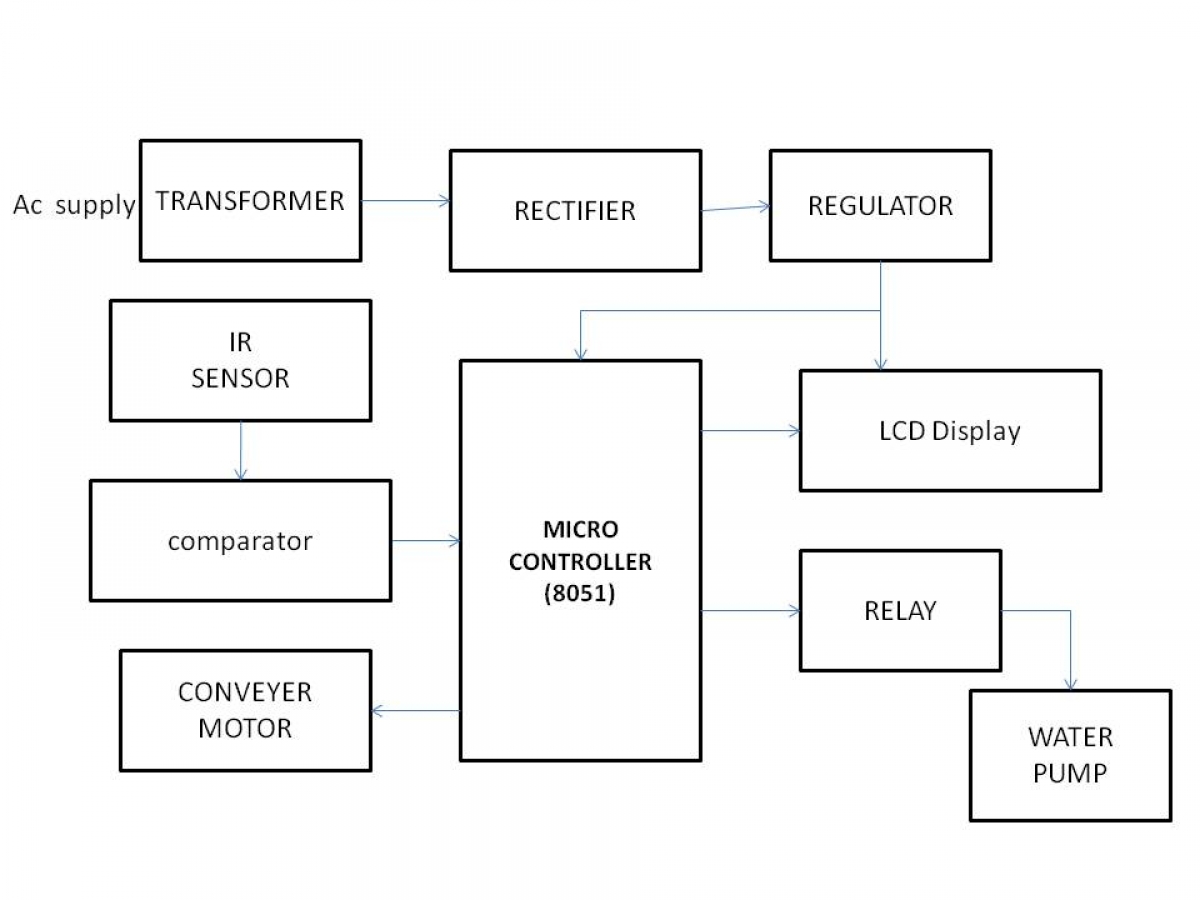

In this system we are using 8051 family as main controller and When signal is given through IR sensor to comparator receives signal from IR sensor according to condition it feds microcontroller and display on lcd display board at same time conveyer motor will start to rotate. And box Come under the filling structure stop the conveyer motor fill it properly time delay is given to it again start conveyer and lastly count the product and conditions are displayed on notice board.

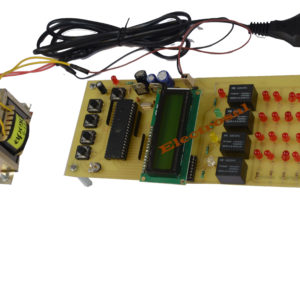

The power supply consists of a step-down transformer 230/12V, which steps down the mains voltage to 12V AC. This is converted to DC using a bridge rectifier and it is then regulated to +5V using a voltage regulator 7805, which is required for the operation of the microcontroller and other components.

NOTE = Automatic conveyer belt for water filling is project of the last year engineering project, BE final year engineering project. This project is used for the BE last year department students. This project is used for the BE last year electronics department student. This project is used BE last year mechanical department students .This project is used BE final year mechanical department project.

Automatic conveyer belt for water filling is the project of good price for the engineering projects. It is vary comparative engineering project. It is project for microcontroller based project. This project is embedded project. This project is sensor based project.

The engineering projects give in the ELECTROSAL HI- TECH PVT.LTD. The best place for the degree and diploma final year engineering projects as well as for mechanical and electronics students’ final year for the golden opportunity.

Automatic conveyer belt for water filling is easy project and idea for the mechanical and electronics degree and diploma base student & 100% output is done.

HIGHLIGHTS

- This project is to develop a industrial automation system conveyer belt with water filling controlled by microcontroller

- Signal is given through IR sensor to comparator

- Modern industries are gradually shifting from conventional man power to centralized control system

BLOCK DIAGRAM

HARDWARE REQUIREMENTS

- Microcontroller

- DC Motor

- IR Sensor

- Conveyer Belt

- Conveyer Wheel

- Relay

- Water tank

- Transformer

SOFTWARE REQUIREMENTS

- Keil

- Eagle

- proteus

Kintali –

It is a best online services where we can purchase documentation. It is very helpful for students to gain more practical knowledge.

Kiran varute –

good

Abhinandan baloji –

One of the best supporting team for projects and cost is too affordable , delivery of the product is also impeccable ?.,staff are also friendly and interactive.

Sadeep Kabir (Canada) –

I ordered this project for my final year project demo. When I was going for testing this project was worked very nicely. Thank you Electrosal for helping me.

Yash Shirole –

I needed a electrical project for final year so I went for this project, the project was well tested also it is in plug and play condition. And it’s impressive as it gives almost accurate results.

Azar Mulla –

A Typical day at work very competitve learned to never to take the objection of one call in to the next management was very encour again when was an off day the morel of the very work was the hards part of the job was tring the leards of the team form month to much the most enjoble part of my job three was the great bounes i received for over achivment

Girish k chaugale –

Very much dedicated , highly skilled team of engineers . Can get the required project at an affordable price in the promised time.

The most important part is after sale service which is very much admirable

Sanjay Mannikere –

Highly skilled and experienced employees. Excellent and Innovative projects delivered/undertaken. Completely dedicated on doing quality products. Great to have a company in our region.

Darshan Parit –

Electrosal Hi Tech pvt Ltd is one of the project centre. They provide practical based knowledge of project. Electrosal team are very good and experienced. Thanks electrosal

Honduran (houdurasa) –

A great level of detail and understanding from these guys. I come from a power background personally, so I struggled a little with an electronic based project. However, Electrosal made this seamless. Through, easy communication and extremely compotent professionals. Highly recommended thanks.