Description

ABSTRACT

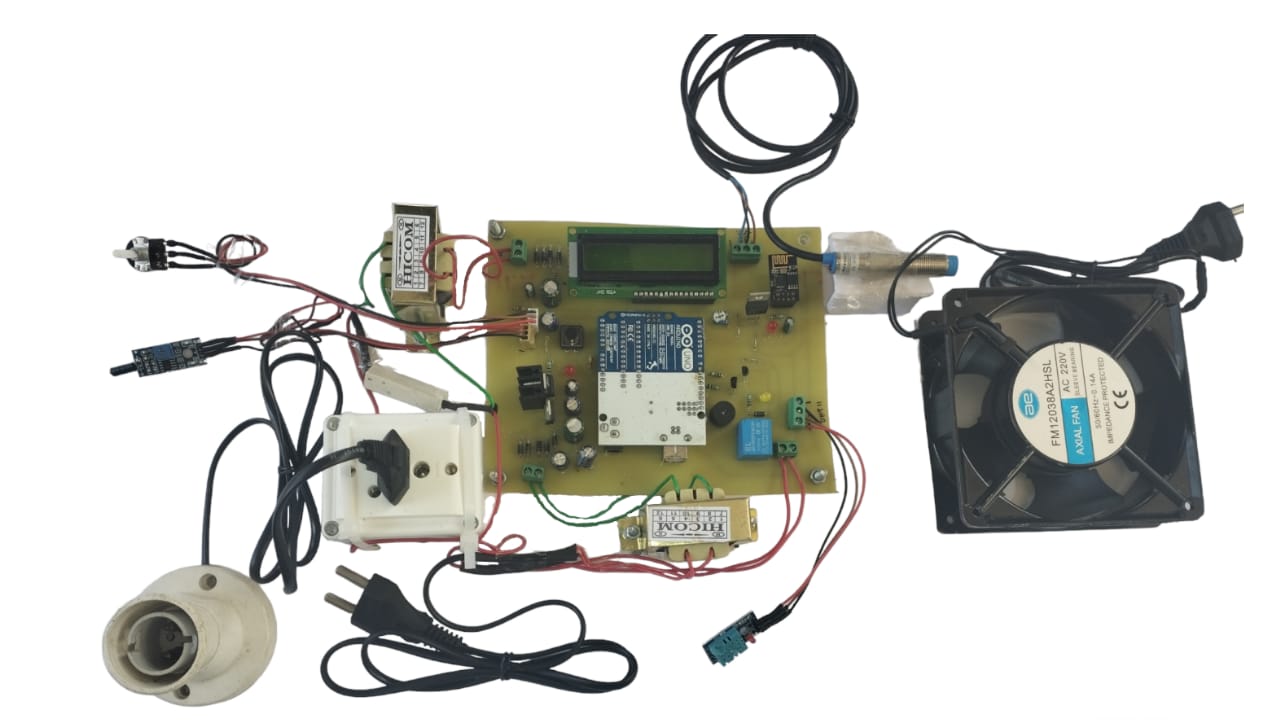

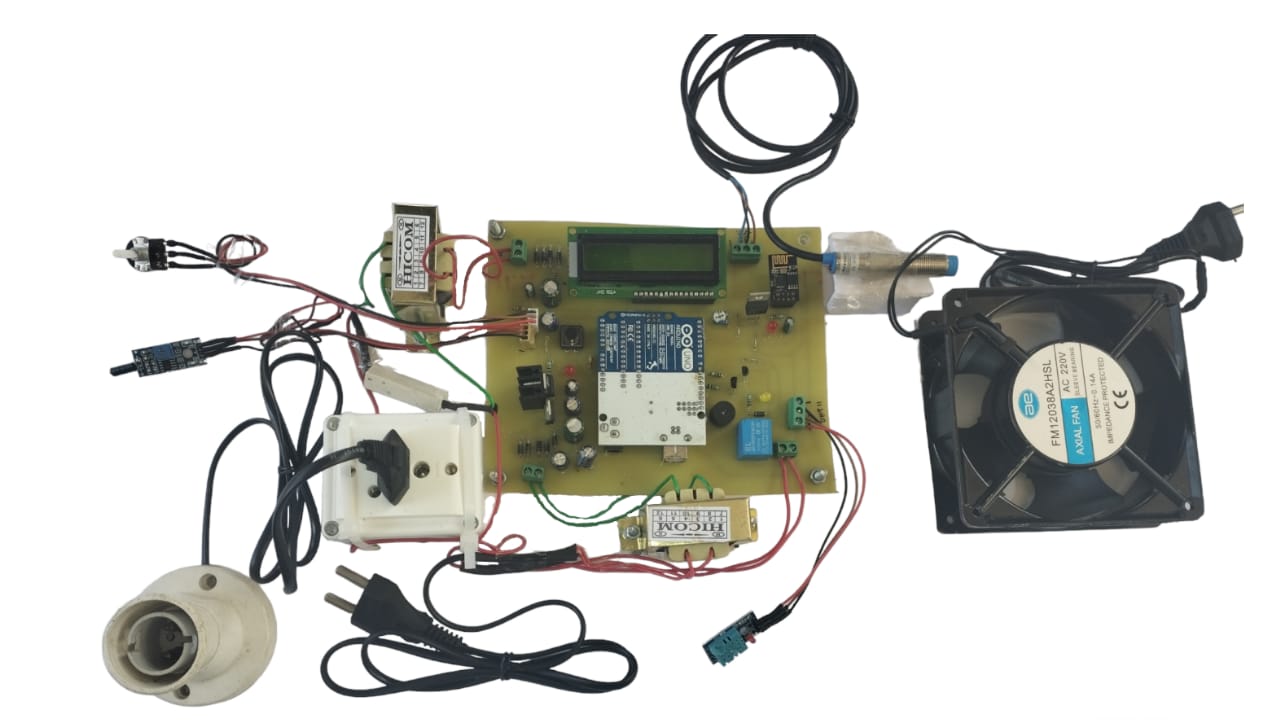

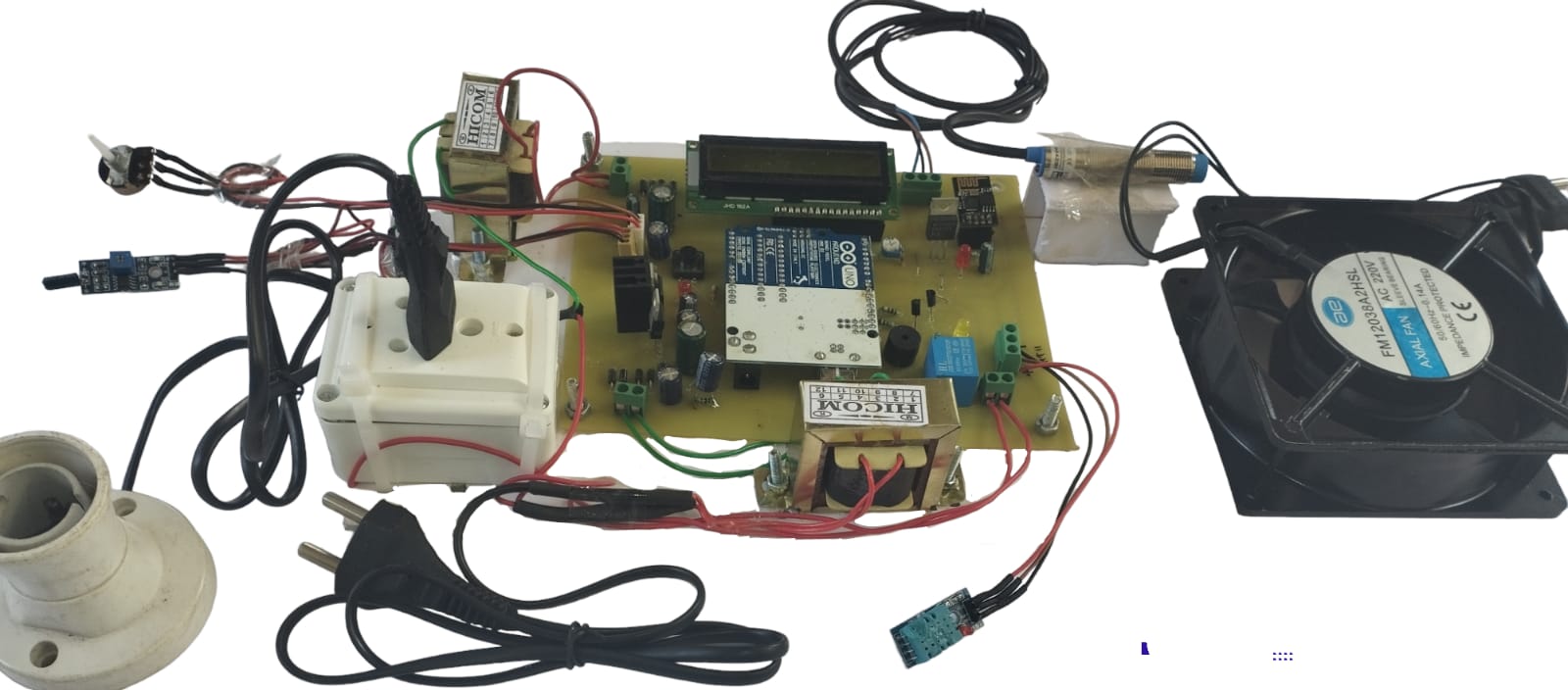

In this project, we give a novel perspective on industrial automation and defect monitoring. Induction motors are used in a variety of sectors. As a result, industrial automation is required for precise and accurate operation. For safe and cost-effective data transmission in industrial settings, the Arduino-based parameter monitoring system for induction motor project presents an induction motor control and monitoring system based on the Arduino communication protocol. The current, voltage, and temperature of an induction motor are all important components in its control system. These critical characteristics have a direct impact on an induction motor’s performance. Controlling the gadgets during continuous operation, on the other hand, is difficult. The Arduino system is used to collect and store data as well as provide control signals to start and stop the induction machine. Some of the issues we monitor are over voltage, over current, and over temperature. By continuously checking for problems and determining preventive maintenance, this strategy will increase machine productivity. Induction motor, Internet of Things, Arduino Uno, and Proteus software are some of the terms used in this project.

Note add –

–

Induction motor protection system using arduino over iotis the project of a good Price for the electronics engineering project. Core Electronics engineering project it is a very comparative engineering project. It is a very good BE final year and diploma project.it is project for sensor based project idea for the core electronics projects it is a project for the sensor based projects.

The engineering projects give in the ELECTROSAL HI- TECH PVT.LTD. The best place for the degree and diploma final year engineering projects as well as for electronics students ‘and core electronics student’s electrical final year for the golden opportunity.

Induction motor protection system using arduino over iotis an easy project and idea for the electronics degree and diploma base students & 100% output is done.

HIGHLIGHTS

1) In this project the concept of the Internet of Things for monitoring motor system parameters remotely

2) Early detection of motor failure.

3) The system has the specific advantage of less maintenance.

4) Prevent system failures by using automatic or manual control methods to start and stop an induction motor’s activity.

5) The most extensively utilised fault detection method.

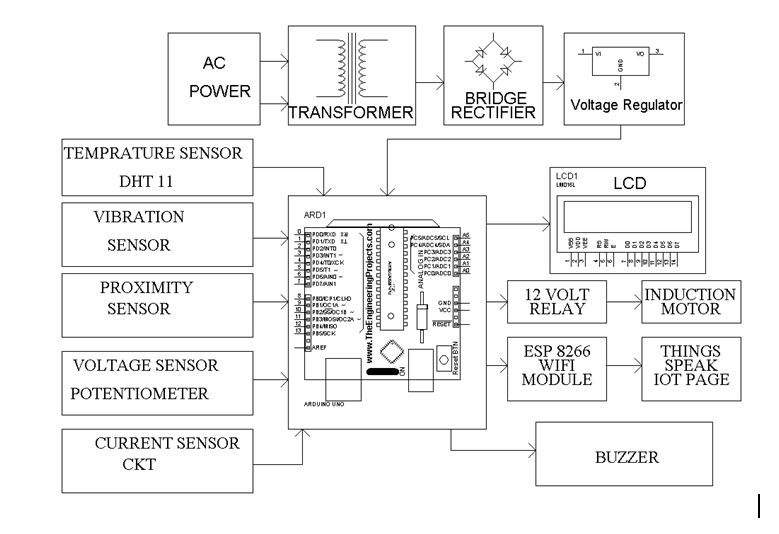

BLOCK DIAGRAM

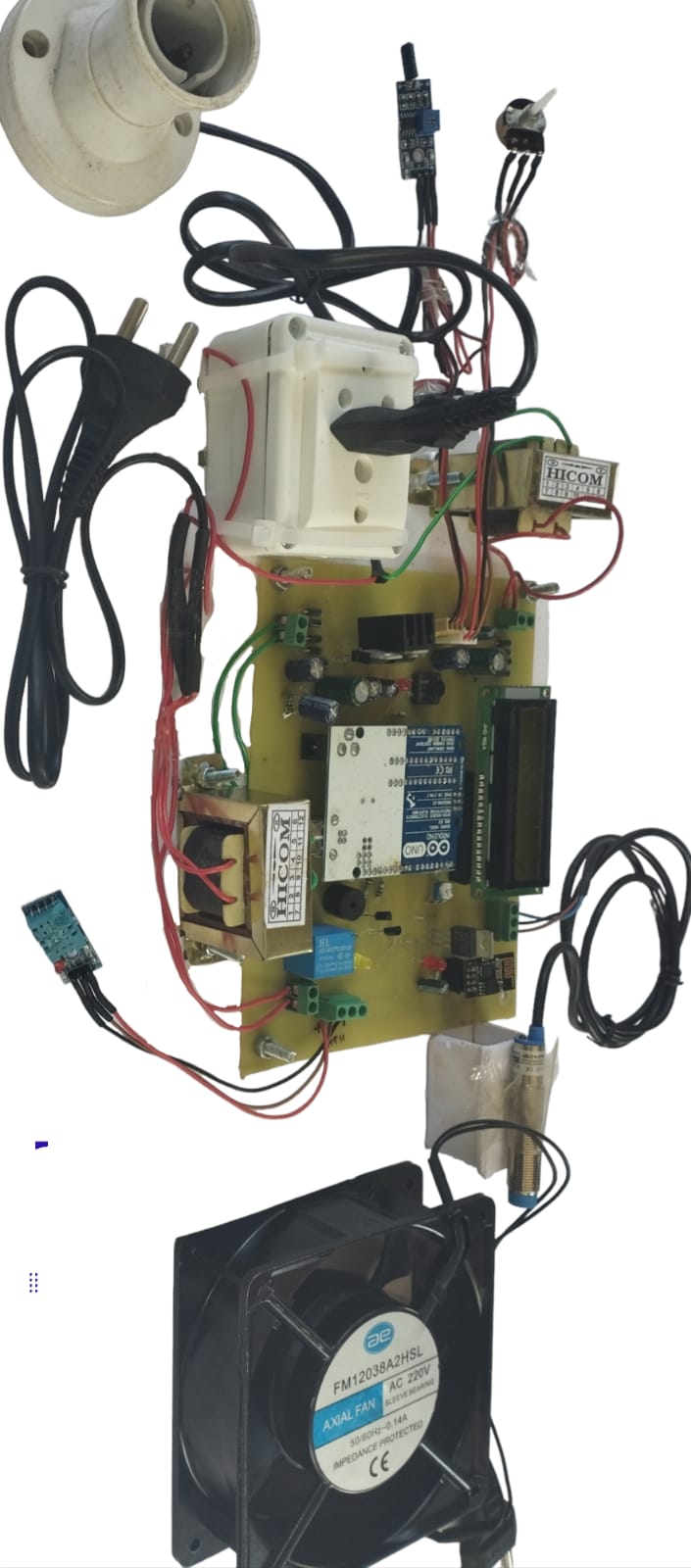

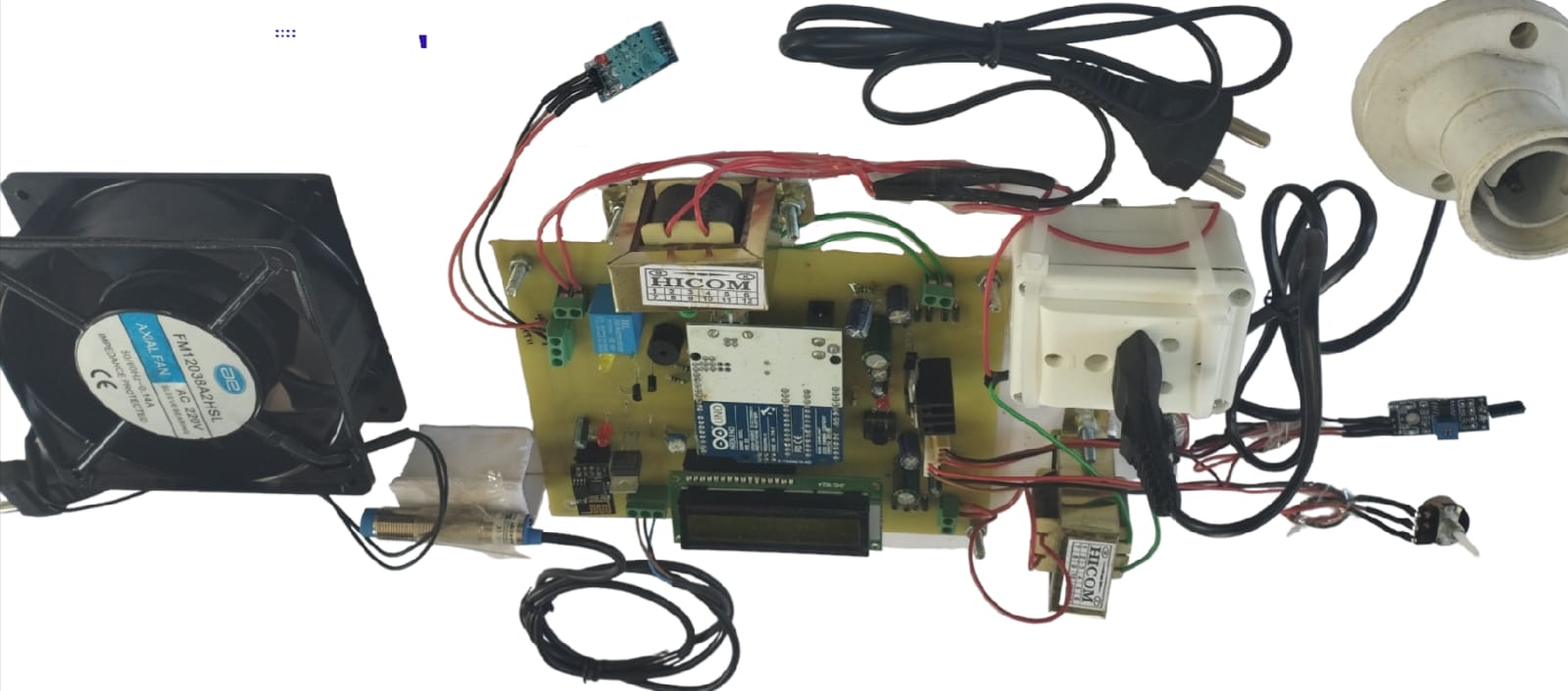

HARDWARE REQUIREMENTS

Transformer

Bridge rectifier

Regulator

LCD display

Arduino

Proximity sensor

Vibration sensor

Temperature sensor

Current circuit

Voltage sensor

Buzzer

Relay

Induction motor

ESP 8266 WIFI module

SOFTWARE REQUIREMENTS

SOFTWAREW REQUIREMENTS

Arduino ide

Eagle

Proteus

Sameer Kurane –

Nice Project

Tanage patankar –

Well i got the AUTOMATIC POWER FACTOR CORRECTION USING ARDUINO project and i was surprised to see it delivered in such a good condition. I was afraid that sending a delicate circuit in through international shipping may damage it, but their packaging is extremely good.

Swati khavre –

I Hired the hanayman conneection to assemble a disk for me the in home free estimate wss convenient and easy jos assembled my desk and went above and beyound i am so happy with the result and next time i have a project that reqaires a carpenter i will ask for him agin jos supper nice effeient and i felt making com fortable wiht him in my home he was very sweet to my two over friendly cast thank you joe for making my life easier

mahi Patil –

yesterday i received my ARDUINO BASED UNDERGROUND CABLE FAULT DETECTION project kit.. kit had all the components and parts as mentioned in component lists. Looking forward to start working on it.