Description

In the present project, a model system is used to investigate the strong magnetic field effects. Considerable segregation is induced by the applied gradient magnetic field, whereas no segregation is observed in a gravity field because of the convection. A high gradient magnetic field, together with the particle size and treatment time, is an important factor in generating the segregation. At the same time, magnetic alignment is detected after the strong magnetic field treatment.

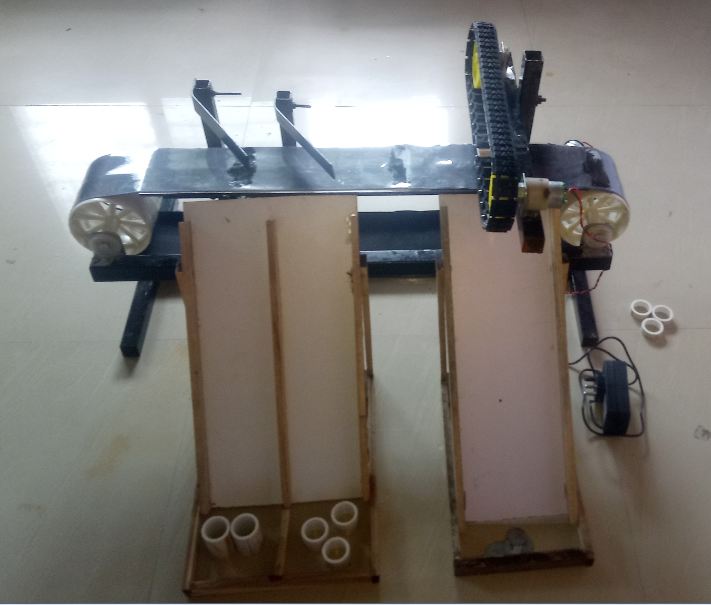

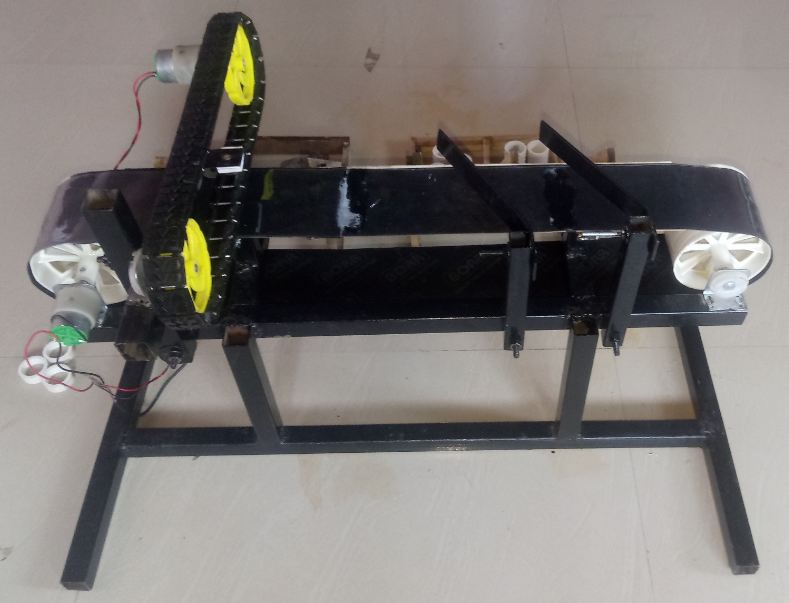

In the manufacturing & assembly industry daily we encounter multiple problems of mixed products. While doing assembling or packing we need to segregate parts as per some characteristic. In this project, we are going to segregate magnetic & nonmagnetic parts. Here we have a structured frame consisting conveyor belt placed on the plane which carries the whole system.

Guide No.1:- First slide is attached to this guide to separate the material which has a height greater than 4.5cm.

Guide No.2:- Second slide is attached to this guide to separate the material having a height of more than 2.5cm.

Guide No.3:- Third slide is attached with the third guide for separation of magnetic and non-magnetic material separation.

HIGHLIGHTS

- This project may reduce the Man Power requirement

- Losses occurring due to Wastage of Iron Chips can be reduced

- Less time-consuming system

- More benefits in minimum investment

- No need for an electronic sensor

- Stopper height can be adjusted

BLOCK DIAGRAM

HARDWARE REQUIREMENTS

- Conveyor belt

- DC motor

- Battery

- Slides

SOFTWARE REQUIREMENTS

- No need of using any software.

Kajal Tiwari –

I have ordered project kit. And your service is very nice and fast

Siddhardhan R –

Delivery given to me was upto the mark and in the estimated time. The product was neatly packed with the additional components.exited and already in love with the product.