Description

The main objective of this project is to avoid physical contact between the motor shaft and tachometer by using a non-contact tachometer in order to make it convinient, while measuring the speed of aBLDC motor.Also using standard contact type tachometer may not feasible in some applications.

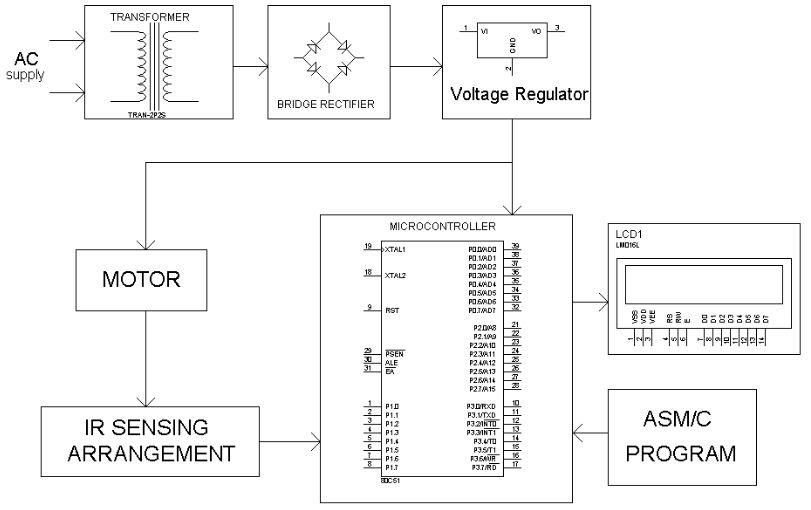

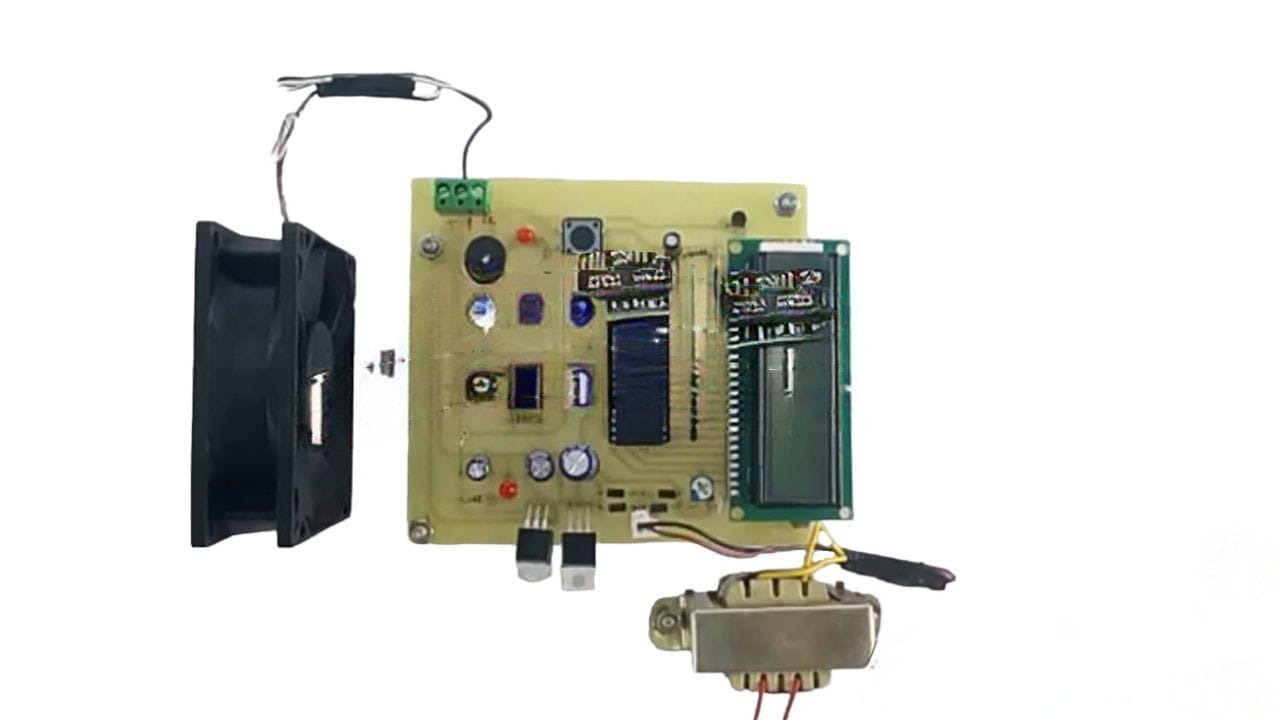

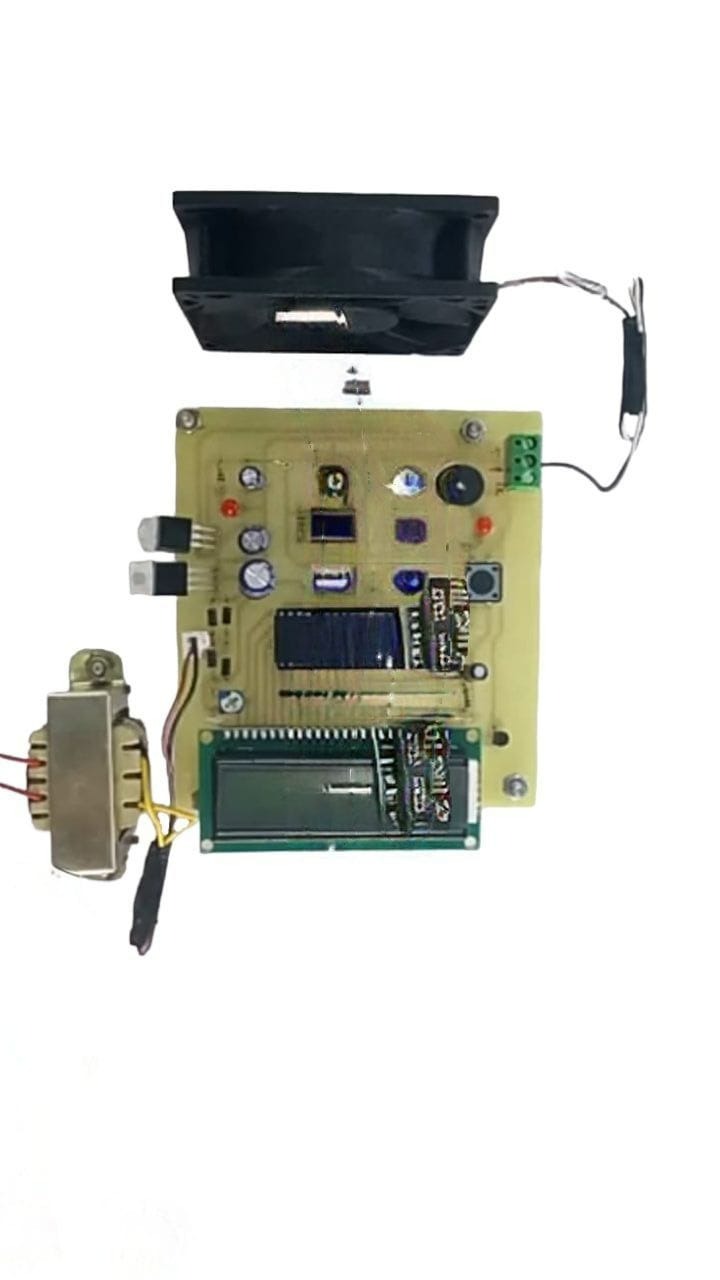

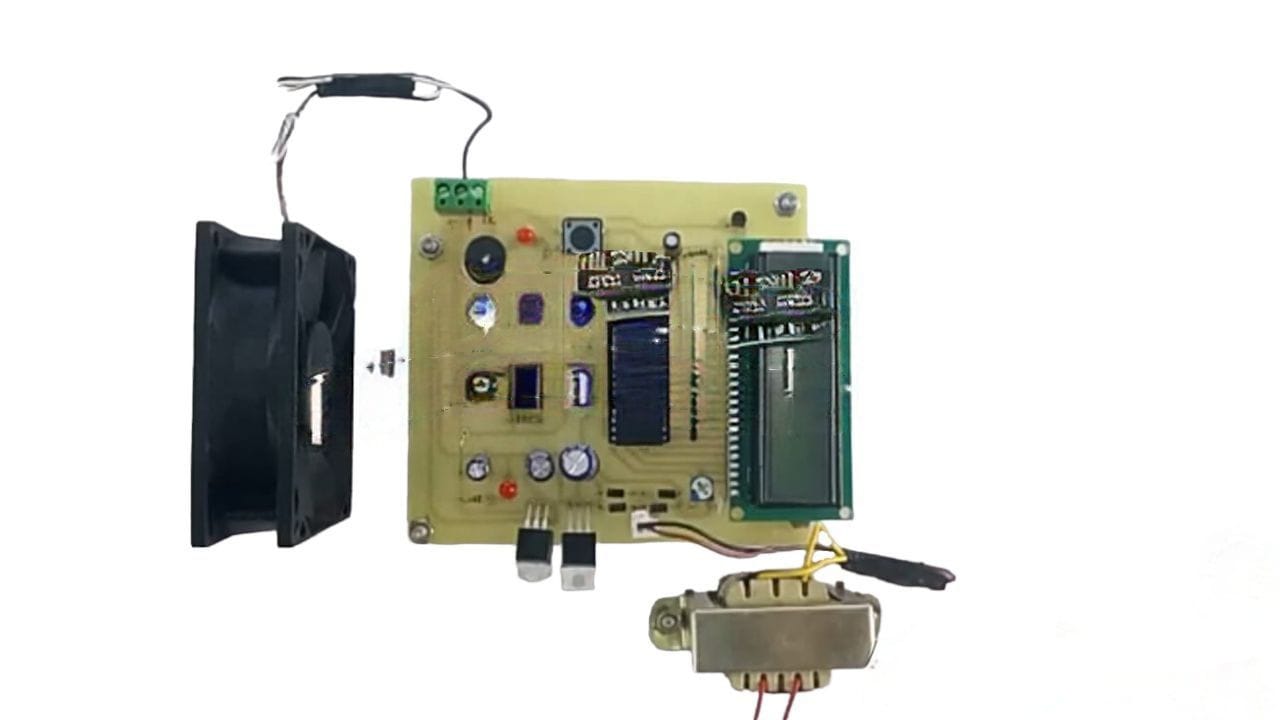

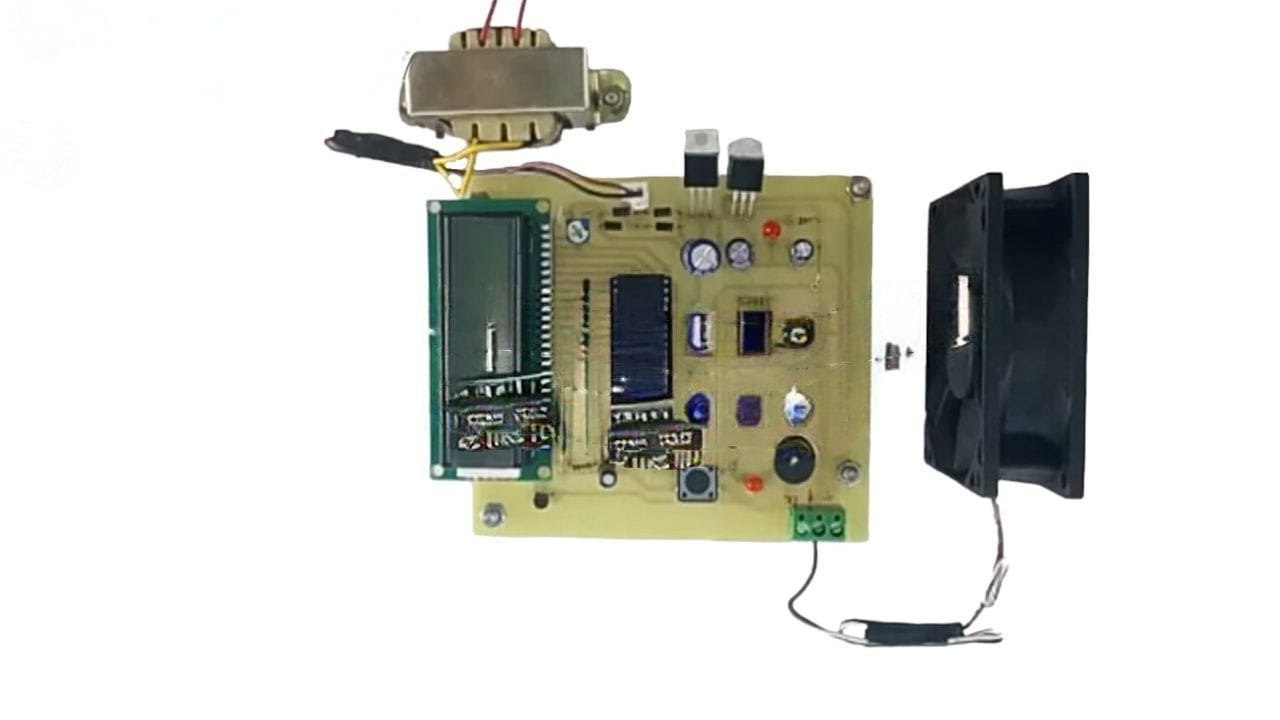

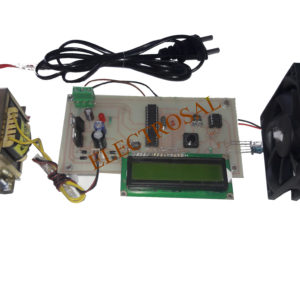

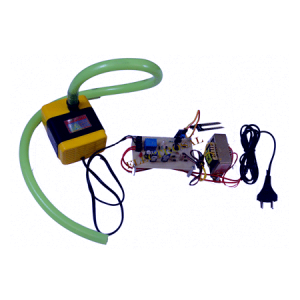

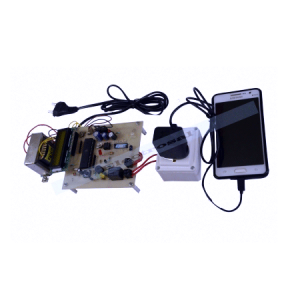

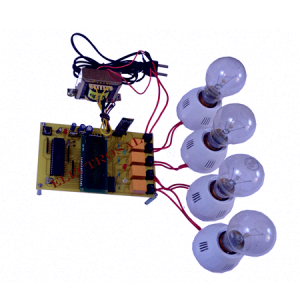

The proposed system uses a microcontroller and a rectified-power supply. An IR transmitter and a photodiode is connected to the controller for measuring the speed of the BLDC motor. A LCD display is interfaced to the microcontroller for displaying the speed information.

This project uses IR light reflection principles. A white patch is mounted on the shaft of the motor. A pair of sensors (Transmitter and receiver) are used to develop a pulse for each reflection that sends an interrupt to the microcontroller. The timer of the controller calculates each pulse received in a particular time intervaland displays the same as RPM (speed) on theLCD display.

The concept of the contact-less tachometer can be enhanced and implemented in the bikes, cars for speed measurement.And thus, the usage of the traditional analog speedometer could be avoided in future.

HIGHLIGHTS

- The main objective of this project is to avoid physical contact between the motor shaft

- The proposed system uses a microcontroller and a rectified-power supply.

- This project uses IR light reflection principles.

- A LCD display is interfaced to the microcontroller for displaying the speed information.

BLOCK DIAGRAM

HARDWARE REQUIREMENTS

- Microcontroller

- LCD display

- Motor

- LM393

- IR sensor

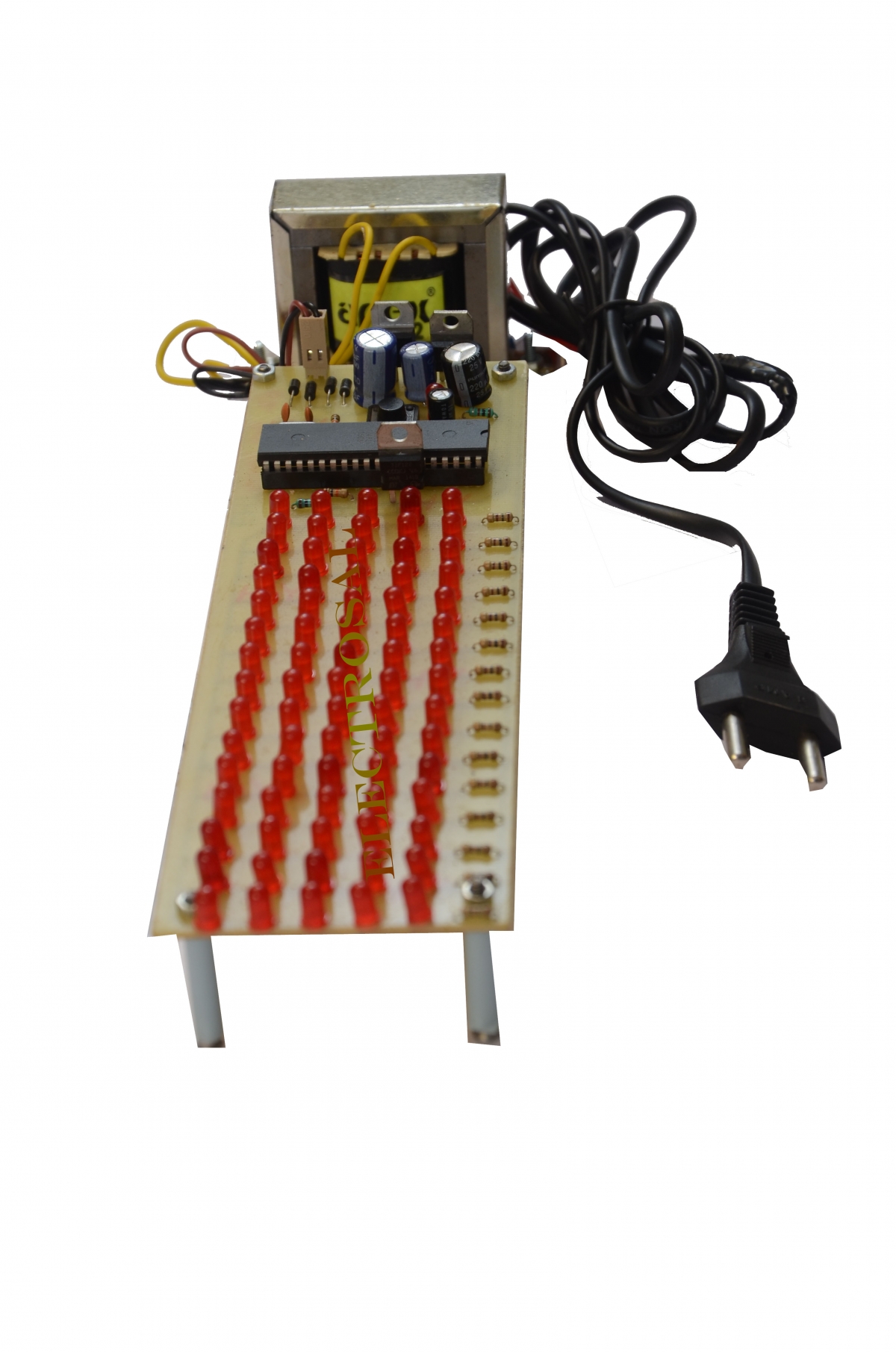

- Transformer

SOFTWARE REQUIREMENTS

- Keil

- Eagle

Rahul sharma –

I have order Do it yourself kit of this project having one ready made kit and another one pcb and their required components. So I have got a great experience.

Prasad –

I have order Do it yourself kit of this project. The project having one ready made kit and another one pcb and their required components. So I have got a great experience.