Description

This report details the implementation of liquid level measurement system using ultrasonic waves. As the human ear audible range is in between 20 Hz to 20 kHz, it is insensitive to ultrasonic waves that falls beyond that range, and hence, the ultrasound waves can be used for applications in industries or vehicles without hindering human activity. They are widely used as range meters and proximity detectors in industries and also in the parking assistance systems. The distance can be measured using pulse-echo and phase-measurement method. In this project, the pulse-echo method is used. The measurement unit uses pulses over continuous signal in the transmission frequency range of ultrasonic transducers. The signal is transmitted by an ultrasonic transducer, reflected by an obstacle and received by another transducer wherein the signal is detected. The time delay of the transmitted and the received signal corresponds to the distance between the system and the obstacle.

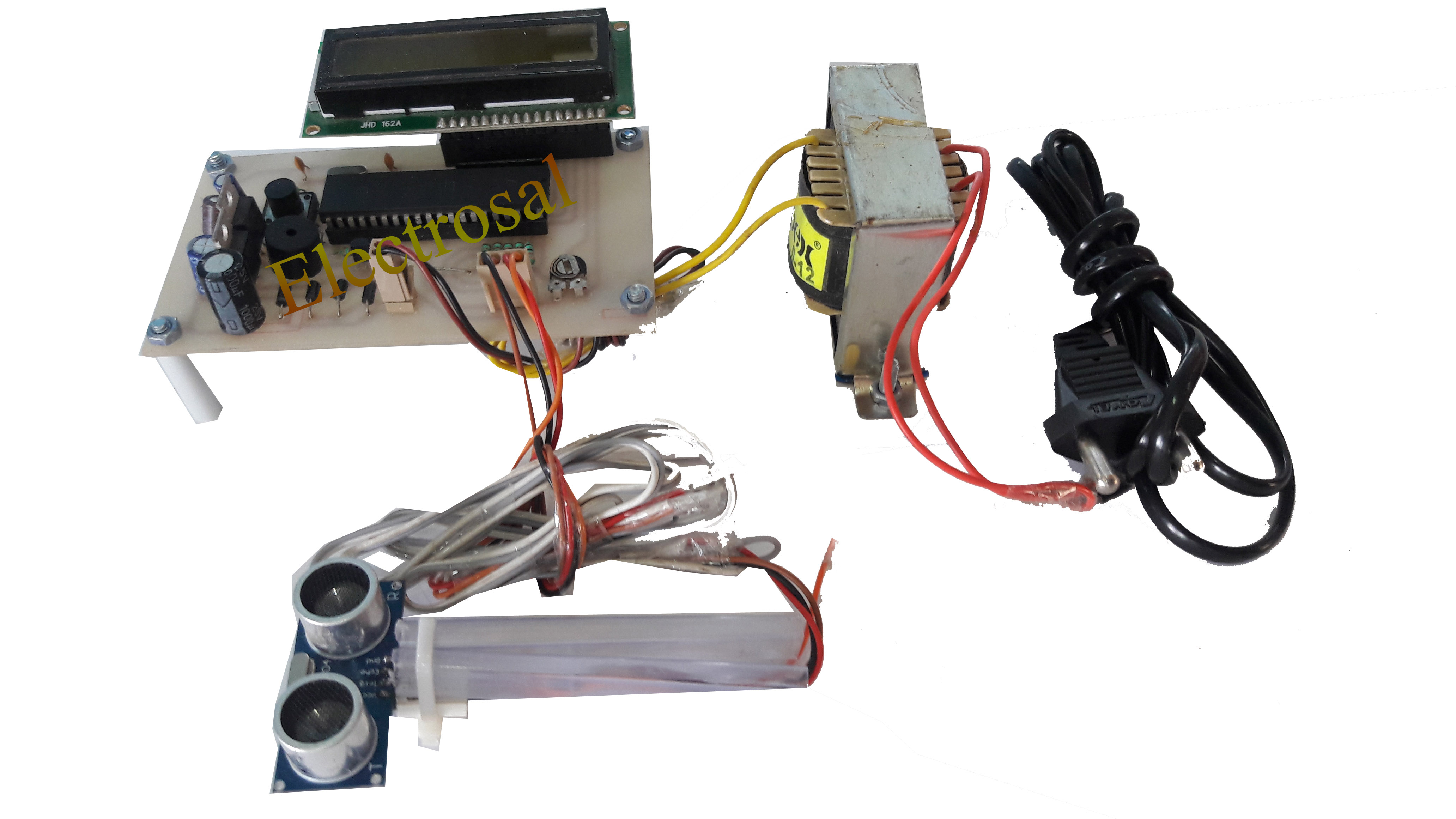

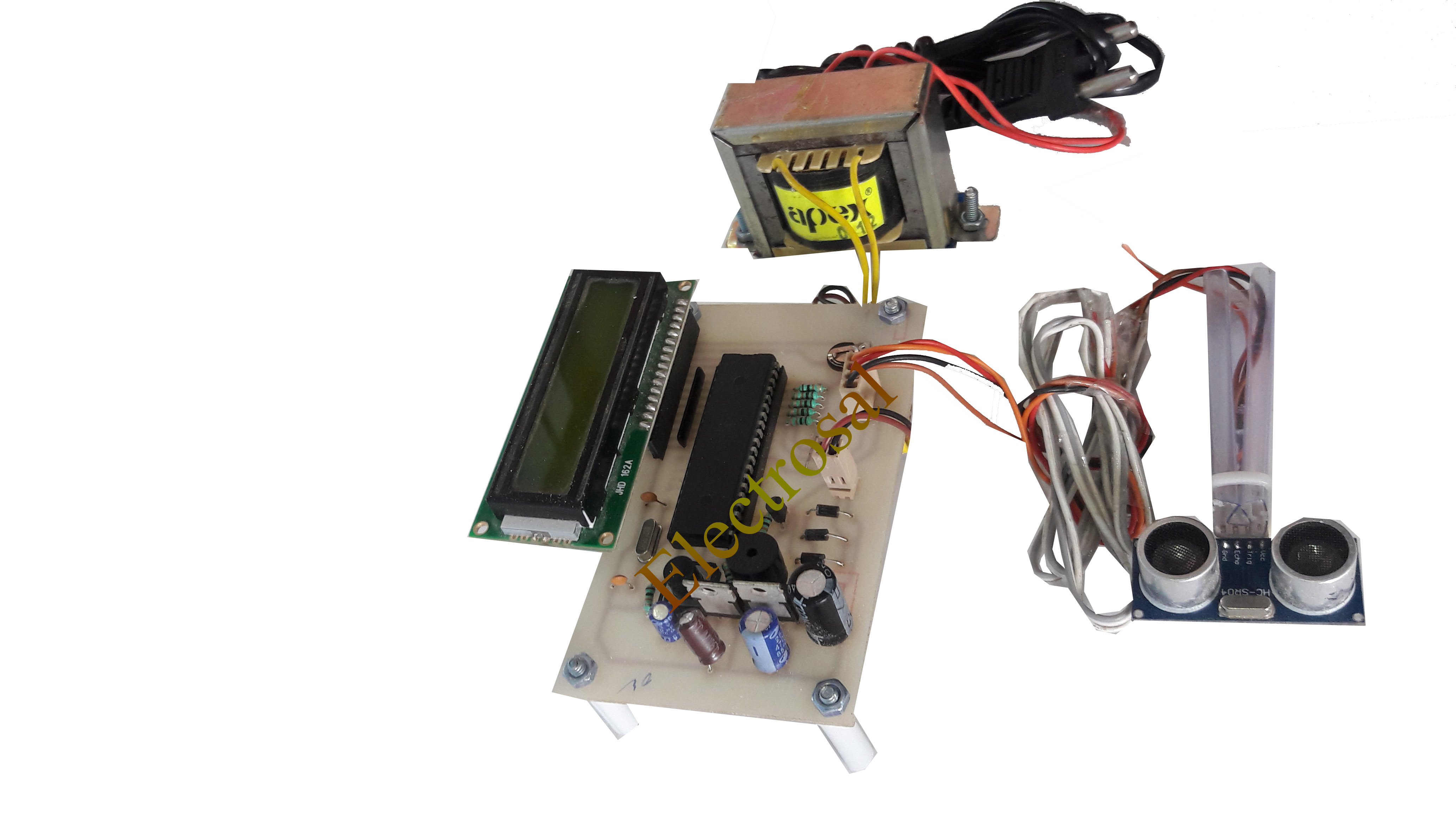

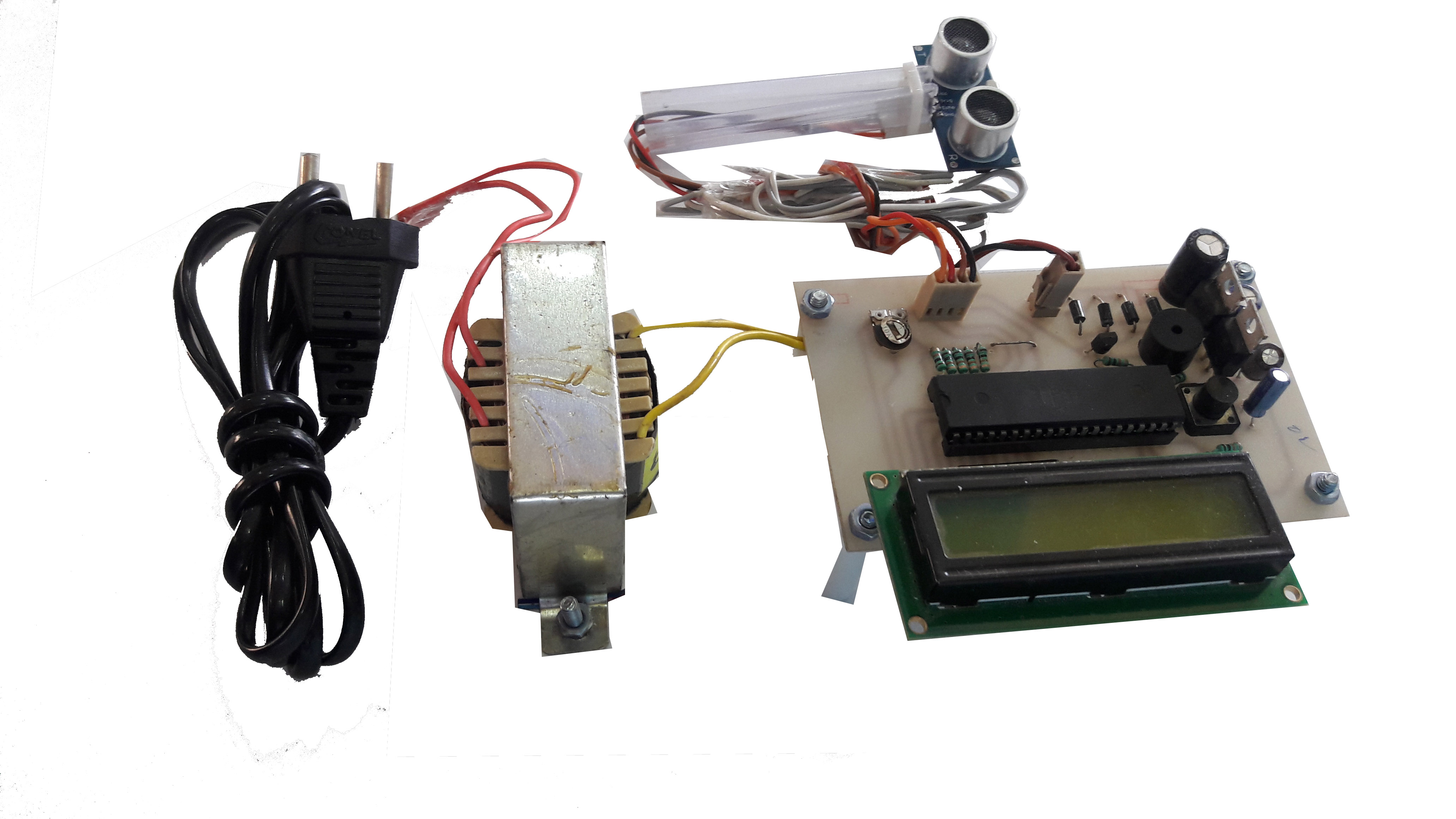

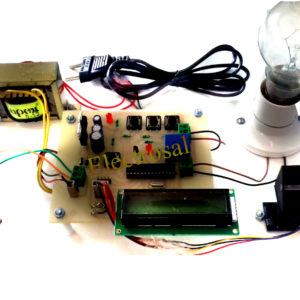

The techniques of liquid level distance measurement using ultrasonic in liquid tank air include continuous-wave and pulse-echo technique. In the pulse-echo method, a burst of pulses is sent through the transmission medium and is reflected by an object (liquid) at a specified distance. The time taken for the pulse to propagate from the transmitter to the receiver is proportional to the distance of the object. In this project, an ultrasonic module is interfaced to the microcontroller, and an ultrasonic transducer comprising of a transmitter and receiver are also used. The transmitted waves are reflected back from the liquid level and received by the transducer. The total time taken from sending the waves to the receiving end is calculated by taking into consideration the velocity of the sound. Then, the distance is calculated by a program running on the microcontroller and displayed on an LCD screen interfaced to the microcontroller.

The power supply consists of a step-down transformer 230/12V, which steps down the voltage to 12V AC. This is converted to DC using a Bridge rectifier. The ripples are removed using a capacitive filter, and it is then regulated to +5V using a voltage regulator 7805, which is required for the operation of the microcontroller and other components.

The scope of the project in future can be heightened by using high-frequency transducers to make it fit for medical applications like ultrasound machine.

HIGHLIGHTS

- This report details the implementation of liquid level measurement system using ultrasonic waves

- the human ear audible range is in between 20 Hz to 20 kHz

- The techniques of liquid level distance measurement using ultrasonic in liquid tank air include continuous-wave and pulse-echo technique.

- . In this project, an ultrasonic module is interfaced to the microcontroller

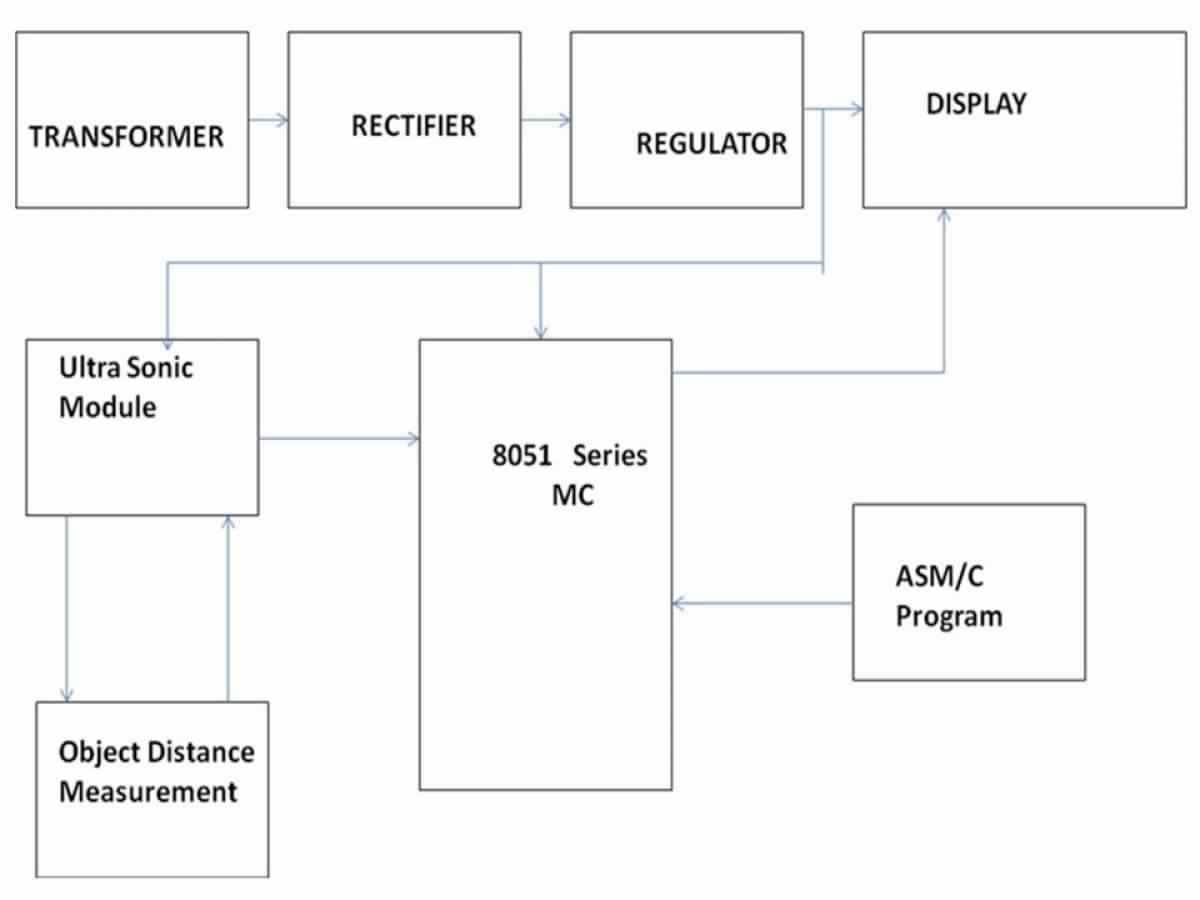

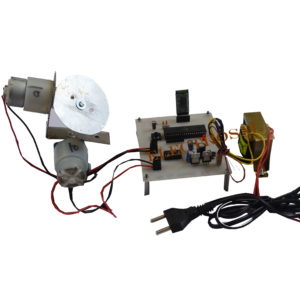

BLOCK DIAGRAM

HARDWARE REQUIREMENTS

- Microcontroller

- Ultrasonic Sensor

- LCD display

- Transformer

SOFTWARE REQUIREMENTS

- keil

- Eagle

- proteus

Swara mohite –

Good

electrosal –

The project quality was very good. I had ordered the wired based security system project kit

Divesh Shaha –

Thank you Electrosal hi tech. They helped me a lot in my project work.once again thank you Electrosal team

Bewuketu Dereje –

To be honest team is doing good job , really fast response to clients problems and our project was well completed on time and recived it without any distortion, really appreciate it thank you electosal team

Bhakti Hanimanale –

Had recently requested for a project and have received it within the time they had informed. They did the follow up right from the start till the end. Was pleased with the responses from the staff.